Engineers develop new materials for hydrogen storage

Published Date

By:

- Ioana Patringenaru

Share This:

Article Content

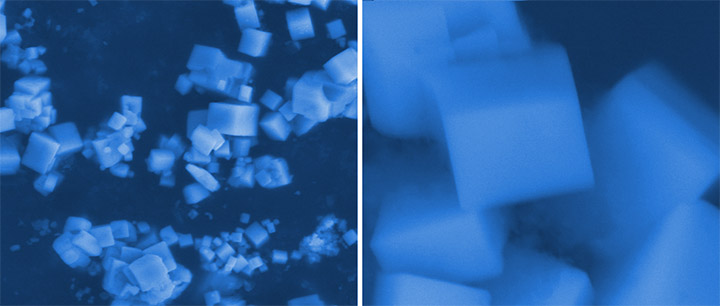

From left, Scanning electron microscope image of the hexaboride structures at 5 microns and 500 nanometers.

Engineers at the University of California, San Diego, have created new ceramic materials that could be used to store hydrogen safely and efficiently.

The researchers have created for the first time compounds made from mixtures of calcium hexaboride, strontium and barium hexaboride. They also have demonstrated that the compounds could be manufactured using a simple, low-cost manufacturing method known as combustion synthesis.

The work is at the proof of concept stage and is part of a $1.2 million project funded by the National Science Foundation, a collaboration between UC San Diego, Alfred University in upstate New York and the University of Nevada, Reno. The manufacturing process for the ceramics is faster and simpler than traditional methods used to manufacture these types of materials. The researchers presented their work in March 2014 at the third International Symposium on Nanoscience and Nanomaterials in Mexico.

“We are looking for solid materials that can store and release hydrogen easily,” said Olivia Graeve, a professor at the Jacobs School of Engineering at UC San Diego, who has gained international recognition as a nanomaterials manufacturing expert.

Storing hydrogen has become increasingly important as hydrogen fuel cells become more popular power sources in industry and elsewhere. But hydrogen, the lightest element on the periodic table, is difficult to store. It tends to diffuse through the walls of pressurized tanks. It also needs to be compressed in order to occupy manageable amounts of space when stored.

The resulting ceramics are essentially crystalline structures in a cage of boron. To store hydrogen, the researchers would swap the calcium, strontium and boron with hydrogen atoms within the cage.

Engineers mixed boron with metal nitrates and organic fuels, such as urea, in a box furnace at temperatures below 400 degrees Celsius—roughly 750 degrees Fahrenheit—cooler than a commercial pizza oven. The nitrates and organic fuels ignite, generating heat that then drives the reaction without the need for an external source of power. This method is known as combustion synthesis.

“It’s a very simple, nice process,” Graeve explained.

Graeve earned a bachelor’s degree in structural engineering from UC San Diego in 1995 before earning a Ph.D. in materials science and engineering from the University of California, Davis in 2001. She was on faculty at the University of Nevada at Reno and Alfred University before joining UC San Diego in 2013.

Graduate student James Cahill will present the work at Research Expo, April 17, at the Jacobs School.

Share This:

You May Also Like

Stay in the Know

Keep up with all the latest from UC San Diego. Subscribe to the newsletter today.