Engineers receive $1 million grant to improve the way robots interact with people in U.S. factories

Published Date

By:

- Ioana Patringenaru

Share This:

Article Content

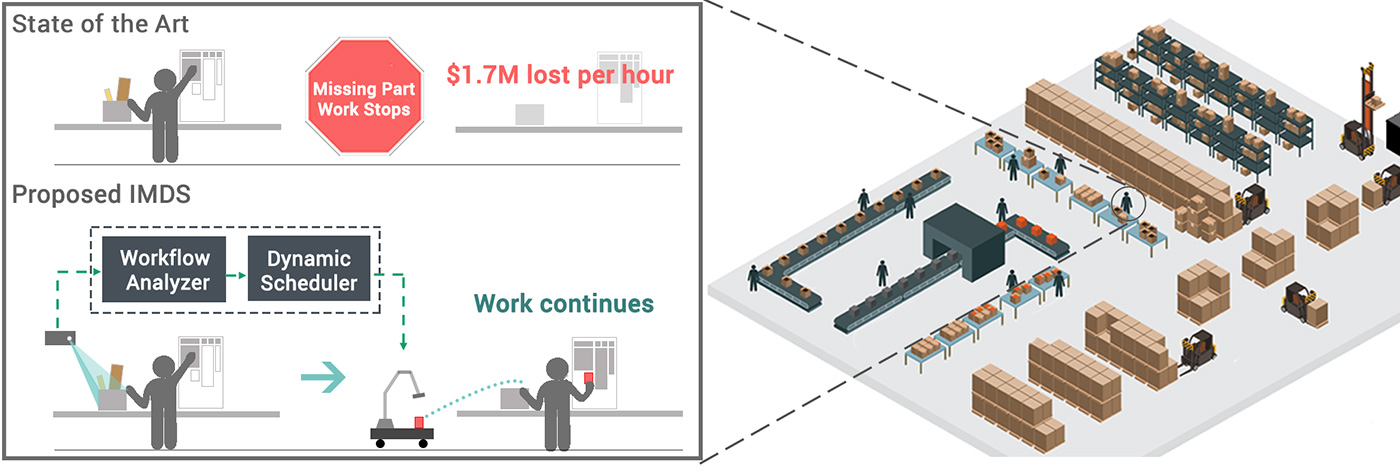

The envisioned intelligent material delivery system: a robot will sense when skilled workers need materials, and deliver them in advance. This will help reduce worker frustration, stress, and talent loss, and save approximately $1.7 million dollars an hour by reducing work stoppage problems.

Laurel Riek, a roboticist at the University of California San Diego, will lead a three-year, $1 million project funded by the National Science Foundation to help change the role of robots in factories and make it easier for machines to work alongside people.

The goal of the project is to design an intelligent material delivery system, which supports and closely integrates with skilled workers in factories. The researchers will investigate innovative, multi-disciplinary approaches to dramatically advance the state of the art in smart manufacturing and human-centered robotics.

“Modern industrial robots are poorly integrated into human workflow, which can cause a lot of frustration and stress for workers,” said Riek, an associate professor in the Department of Computer Science and Engineering at UC San Diego. “The goal of this project is to enable skilled workers to focus on the tasks they enjoy--their trade--and have robots do the frustrating work, like moving materials around a large factory.”

This robot will deliver materials to workers.

In the system the researchers envision, robots would sense when skilled workers need materials and deliver them in advance. This would save companies, and consumers, about $1.7 million per hour—the cost of lost productivity when work stops to procure the needed materials.

Researchers will team up with Steelcase, a furniture company headquartered in Grand Rapids, Mich. to design and test the system. Each piece of furniture at Steelcase is made to order, so there are millions of variations in material requirements that the system can learn from. The system will be able to estimate material needs on the fly by using machine learning techniques and then instruct robots to fetch items automatically.

The work will be translatable across a wide range of manufacturing sectors, including automotive, construction, healthcare, energy, and goods. This project will help the U.S. manufacturing sector --25% of all domestic employment--dramatically improve their operations by using automation to directly support a talented, skilled workforce. It will help U.S. companies reshore operations, and create new opportunities for U.S. workers to acquire STEM skills.

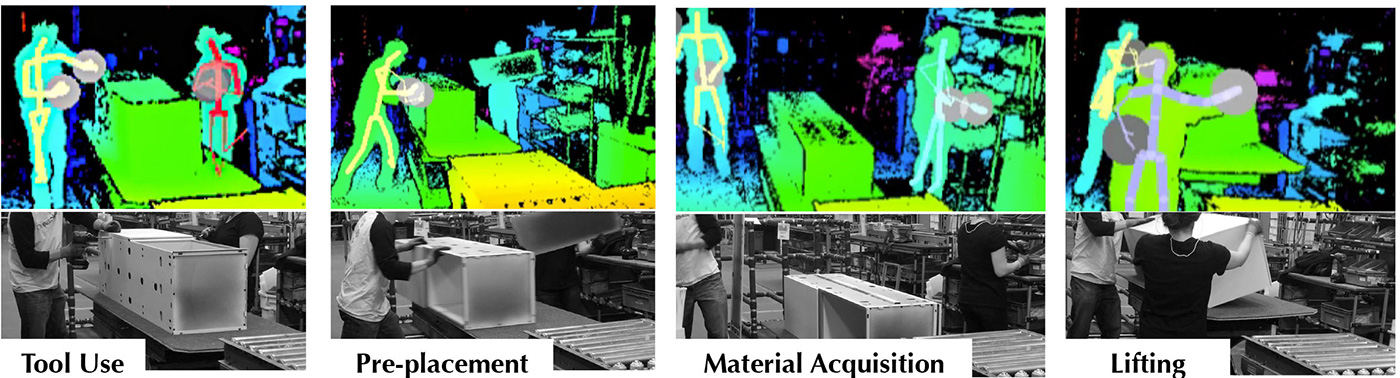

This is a sample task decomposition for a filing cabinet assembly at the Steelcase Grand Rapids, Mich. plant. Every piece of furniture at Steelcase is made-to-order so there are millions of variations in material requirements at any given time. The materials delivery system system will be able to estimate material needs on-the-fly using machine learning techniques, in order to instruct a robot to fetch materials automatically.

The project will also allow researchers to study on multiple workers the impact of the transition from traditional material delivery to intelligent material delivery using robotics. Understanding reactions to such change will allow researchers and companies to optimize systems not only for workflow and task efficiency but also for the human experience. Such knowledge is critical to maintaining job satisfaction, safety and health, and long-term well-being of people in the workforce.

In addition to UC San Diego, the project brings together researchers from the Massachusetts Institute of Technology (Julie Shah, Aerospace and Aeronautics) and the University of Colorado at Boulder (Matthew Hallowell, Civil, Environmental, and Architectural Engineering).

Share This:

You May Also Like

Stay in the Know

Keep up with all the latest from UC San Diego. Subscribe to the newsletter today.