Setting the Stage for Solid-State Battery Success

An innovative research project funded by the LG Energy Solution has generated research and thought leadership that are poised to help all-solid-state batteries move from research labs toward widespread use.

Published Date

By:

- Daniel Kane

Share This:

Article Content

Battery researchers and other engineers from University of California San Diego, with collaboration from the LG Energy Solution, have published a forward-looking perspective article in the journal Joule.

In the article, the researchers outline three categories of engineering challenges that must be solved in order to transition all-solid-state batteries from the laboratory toward large-scale industrial manufacturing. These three challenges are that of precursors, processing and pressure.

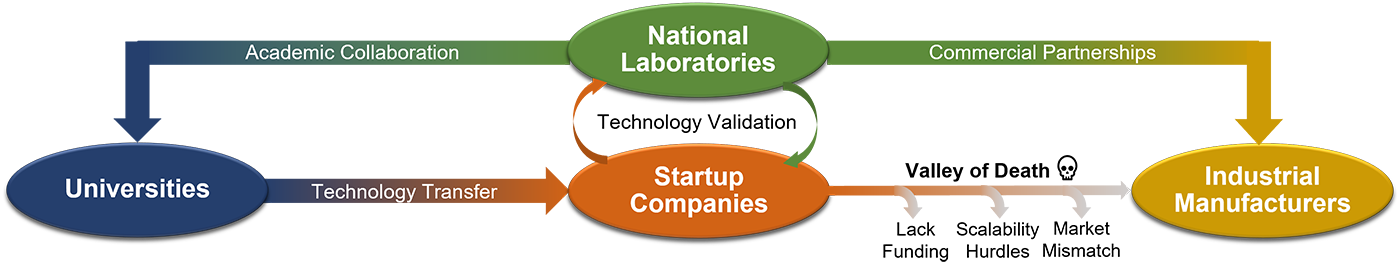

Accelerating scale-up of new battery technologies through university, national laboratory and industry partnerships. Importance of incentivizing transfer of knowledge and know-how through private-public funded collaborative efforts, avoiding the common death valleys of risky start-up companies, where vital intellectual property and development know-how are lost. Image courtesy of Joule

The research and thought leadership contained in the article were made possible through the collaborative efforts between engineers at UC San Diego and the LG Energy Solution through a Frontier Research Laboratory Program, in addition to funding from the US National Science Foundation (NSF).

Engineering and scalability challenges remain

The drivers for this article are recent scientific developments that have created pathways for all-solid-state batteries with energy densities that are significantly higher than conventional lithium ion batteries. Some of these advances include thick dry cathode electrodes, as well as the use of purely metallic alloys or alkali metal anodes. With these and related advances, the massive remaining challenges are in engineering and scalability, both in terms of making the batteries themselves in sufficiently large form factors, and in terms of manufacturing these batteries at large scale.

The three areas where engineering challenges must be solved in order to make big steps toward consumer success of all-solid-state batteries are highlighted as precursors, processing and pressure.

Precursors of solid electrolytes

For all-solid-state batteries to compete in consumer markets, they must be cost competitive ($ per kWh). One of the bottlenecks to this are solid electrolytes, which are a key enabling technology of all-solid-state batteries. Currently, costs of solid electrolytes per kilogram are two orders of magnitude higher than liquid electrolytes.

Two key drivers of the high price of solid electrolytes are: 1) immature supply chains for precursors; and 2) a lack of understanding of scalable synthesis methods for solid electrolytes.

Beyond raw material costs, the authors of the Joule perspective also discuss solid electrolyte synthesis and conditioning steps. They demonstrate that with proper optimization and handling under dry room conditions, the time and resources needed to produce these materials can be significantly reduced while ensuring that they are up to spec.

Processing

Most work conducted today on all-solid-state batteries is still done manually. The tools and infrastructure to support the scalable processing and integration of solid electrolytes into the required composite layers in the battery do not yet exist. Instead, intensive customization is required to fit each process.

To overcome this, the engineers who wrote the new perspective in Joule designed processes to adopt lithium-ion-compatible machinery in the production of all-solid-state batteries. In a notable example in the article, Z-stacking of solid electrolyte sheets and electrodes was demonstrated. Z-stacking is a common technique used in lithium ion batteries but never thought to be possible in all solid state batteries before.

Pressure

Due to the solid nature of materials in the chemistries used in all-solid-state batteries, poor contact at interfaces is typically compensated for by applying high stack pressure on the battery. These high stack pressure requirements are often a point of criticism when discussing use of all-solid-state batteries in electric vehicles. The authors highlight a severe lack of knowledge of the factors determining stack pressure at the module to pack level, as well as its implications on energy density efficiency losses.

To work to address these gaps in knowledge, the authors share key considerations for all-solid-state battery module design. They highlight that beyond the specific value of pressure that the battery community has largely focused on, attention should also be given to pressure uniformity and on how pressure can be maintained while the battery is in operation.

What's next?

The engineering challenges within the categories of precursors, processing and pressure are, no doubt, daunting. This is especially true within university research environments.

Battery research at universities is typically focused on discovery and novel use of materials at small scales. This kind of research often does not include the resources needed to scale discoveries so that they are readily relevant for transfer to industry. Additionally, the authors point out that current academic evaluation systems often provide limited incentives for university scientists to bridge this gap. While battery start-up companies often attempt to fill the scalability gaps between university and industry, this leads to various forms of information protection, resulting in loss of valuable knowledge gained through the practice of engineering and failed iterations.

In this and related ways, the all-solid-state battery field is currently faced with an inefficiency gap when it comes to solving and sharing the tough engineering challenges that stand in the way of large-scale use of all-solid-state batteries in a wide variety of industries.

The authors of the perspective article in Joule argue that, when it comes to all-solid-state batteries, the gap between university research and large-scale manufacturing must be bridged via approaches that don't rely just on start-up companies.

One approach, the authors argue, is to more heavily leverage the research infrastructure and expertise of US National Laboratories. In fact, US National Laboratories have the infrastructure that could support more scaling up research from the small-scale projects performed at universities to larger pilot-scale projects. These kinds of mid-level laboratories could be better utilized to pursue research that is relevant to both university and industry researchers.

This would lead to a more open and dynamic research and innovation ecosystems for all-solid-state battery development. In these kinds of ecosystems, researchers at universities, US National Laboratories, start-ups, and established industry players would be more able to benefit from pre-competitive engineering advances in precursors, processing, and pressure that must be achieved to move the entire field forward.

In fact, one of the authors of this paper, Shirley Meng, is now Chief Scientist of the Argonne Collaborative Center for Energy Storage Science (ACESS) in addition to her role as Professor of Molecular Engineering at The University of Chicago. Meng also serves as Adjunct Professor at the UC San Diego Jacobs School of Engineering.

Paper title

"Scaling up high-energy-density sulfidic solid-state batteries: A lab-to-pilot perspective," published in the journal Joule.

Authors

Darren H.S. Tan, Ying Shirley Meng, and Jihyun Jang from the Department of NanoEngineering at the UC San Diego Jacobs School of Engineering.

Ying Shirley Meng is now at the Pritzker School of Molecular Engineering at The University of Chicago. Meng is also Chief Scientist of the Argonne Collaborative Center for Energy Storage Science

Funders

This work was funded by the LG Energy Solution through the Frontier Research Laboratory (FRL) Program, and by the National Science Foundation—Partnerships for Innovation (NSF-PFI) grant no. 2044465. The authors acknowledge the support of UNIGRID Battery, a UC San Diego spin-out company for the ASSB prototyping capabilities. The authors would also like to acknowledge the UC San Diego Crystallography Facility. This work was performed in part at the San Diego Nanotechnology Infrastructure (SDNI) of UC San Diego, a member of the National Nanotechnology Coordinated Infrastructure, which is supported by the National Science Foundation (grant ECCS-1542148), along with the use of facilities and instrumentation supported by NSF through the UC San Diego Materials Research Science and Engineering Center (UCSD MRSEC), grant #DMR-201192.

Share This:

You May Also Like

Stay in the Know

Keep up with all the latest from UC San Diego. Subscribe to the newsletter today.