Supercomputers Reveal True Strengths of Some Zirconia Ceramics

Simulations suggest applications ranging from prosthetics to aerospace engines

Published Date

By:

- Kimberly Mann Bruch

Share This:

Article Content

For thousands of years, humans have produced ceramics by simply combining specific minerals with water or other solvents to create ceramic slurries that cure at room temperature and become some of the hardest known materials. In more recent times, zirconia-based ceramics have been useful for an array of applications ranging from dental implants and artificial joints to jet engine parts.

Researchers from the Colorado School of Mines have been using multiple supercomputers – Comet at the San Diego Supercomputer Center (SDSC), Stampede2 at the Texas Advanced Computing Center (TACC), and Bridges at the Pittsburgh Supercomputing Center (PSC) – to study certain characteristics of zirconia. The team recently published their findings in the Journal of the European Ceramic Society.

According to corresponding author Mohsen Asle Zaeem, a mechanical engineering professor at the Colorado School of Mines, the study focused on creating supercomputer simulations that show zirconia-based ceramic’s ability to withstand harsh conditions as well as the extreme limits of fracture and fatigue.

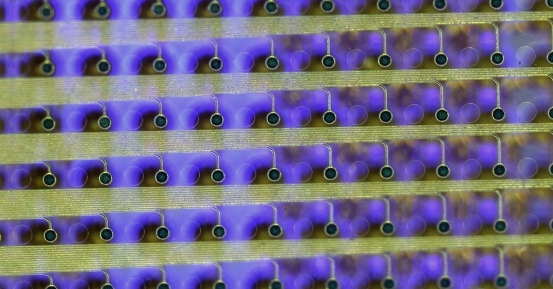

“By using large-scale atomistic simulations, these simulations revealed to us how specific type nanoscale structures, twin boundaries, and pre-existing defects control the mechanical behavior and the corresponding plastic deformation of an advanced shape memory ceramic called yttria-stabilized tetragonal zirconia or YSTZ,” explained Asle Zaeem. “Some important applications, such as jet engines, require advanced materials that can perform reliably at extreme conditions. Shape memory ceramics have shown superior properties at those higher temperatures such as high strength and excellent oxidation/corrosion resistance. Addressing their deformation, fracture, and fatigue limitations will open the door for creating the next generation of high-temperature materials.”

This research was supported by the U.S. Department of Energy, Office of Science, Basic Energy Sciences, (DE-SC0019279).

Share This:

You May Also Like

Stay in the Know

Keep up with all the latest from UC San Diego. Subscribe to the newsletter today.